How to Select a Vibration Isolator for Optimal Performance

The Basics of Vibration Isolation

Vibration isolation plays a vital role in safeguarding equipment and optimizing its performance by reducing the impact of unwanted vibrations. These disturbances, often originating from machinery, environmental factors, or external forces, can lead to excessive wear, noise, and operational inefficiencies. Employing a vibration isolator ensures smoother operation, longer equipment life, and consistent reliability in demanding environments.

Key Factors in Selecting a Vibration Isolator

Choosing the right vibration isolator requires careful consideration of several factors to ensure optimal performance and equipment protection. Here are the key elements to evaluate:

- Load Capacity: Ensure the isolator can support the weight of your equipment without compromising effectiveness.

- Frequency Range: Match the isolator’s performance range with the frequency of vibrations generated by your equipment.

- Environmental Conditions: Account for factors such as temperature, humidity, and exposure to chemicals that may impact the isolator’s durability.

- Space Constraints: Evaluate the available space to determine the isolator size and configuration that fits best.

- Material Selection: Consider isolators made from materials like rubber, metal, or composites depending on application needs.

Exploring Types of Vibration Isolators

When selecting a vibration isolator, understanding the available types is essential. Below is a breakdown of the most common options:

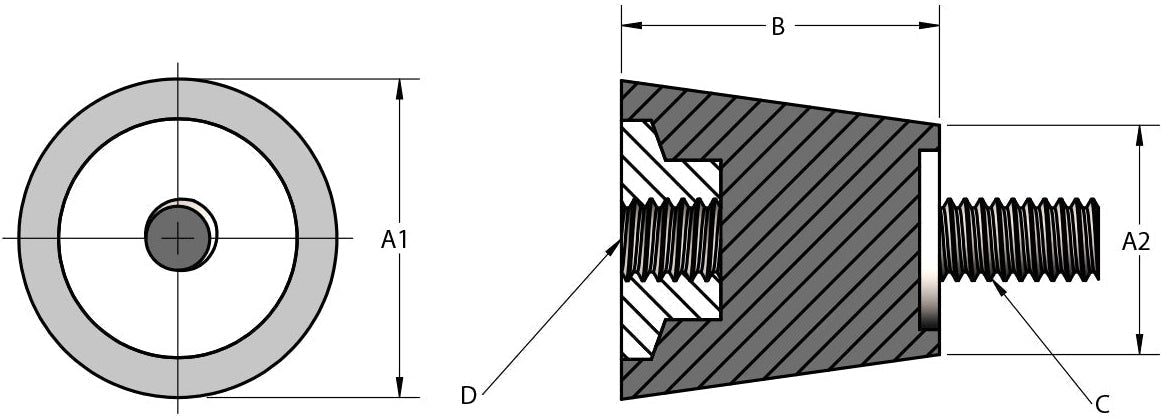

Elastomeric Mounts

- Material: Rubber or similar compounds.

- Use: Ideal for damping high-frequency vibrations.

- Applications: Industrial machinery, HVAC systems.

Wire Rope Isolators

- Features: Flexible and corrosion-resistant.

- Use: Handles extreme temperatures and harsh environments.

- Applications: Military, aerospace, and marine equipment.

Air Springs

- Mechanism: Pressurized air for vibration damping.

- Use: Heavy machinery and precision tools.

- Benefits: Adjustable to different load capacities.

Metal Spring Isolators

- Design: Robust and long-lasting.

- Use: Effective for low-frequency vibration isolation.

- Applications: Large industrial machines.

Steps to Determine the Appropriate Isolator

Selecting the right vibration isolator involves a few essential steps to ensure compatibility and performance. Start by assessing the equipment's specifications—its weight, size, and the frequency of vibrations it generates. Next, take environmental factors into account, such as temperature, humidity, and chemical exposure, to ensure the isolator materials can endure the operating conditions.

Space constraints are another key consideration. Measure the available area and choose a design that fits seamlessly into your setup. Finally, review manufacturer guidelines and technical data to confirm your choice. For unique or complex applications, consulting an expert can provide valuable insights.

This streamlined approach ensures you select the best isolator for your needs, enhancing equipment efficiency and durability.

Why Choose Enterprise Rubber for Vibration Isolators?

Enterprise Rubber offers high-quality vibration isolators designed to meet the unique needs of diverse industries. With a focus on durability, precision, and reliable performance, their products help protect equipment, reduce downtime, and improve operational efficiency. Backed by expert support and extensive industry experience, Enterprise Rubber ensures you find the ideal solution for your application.