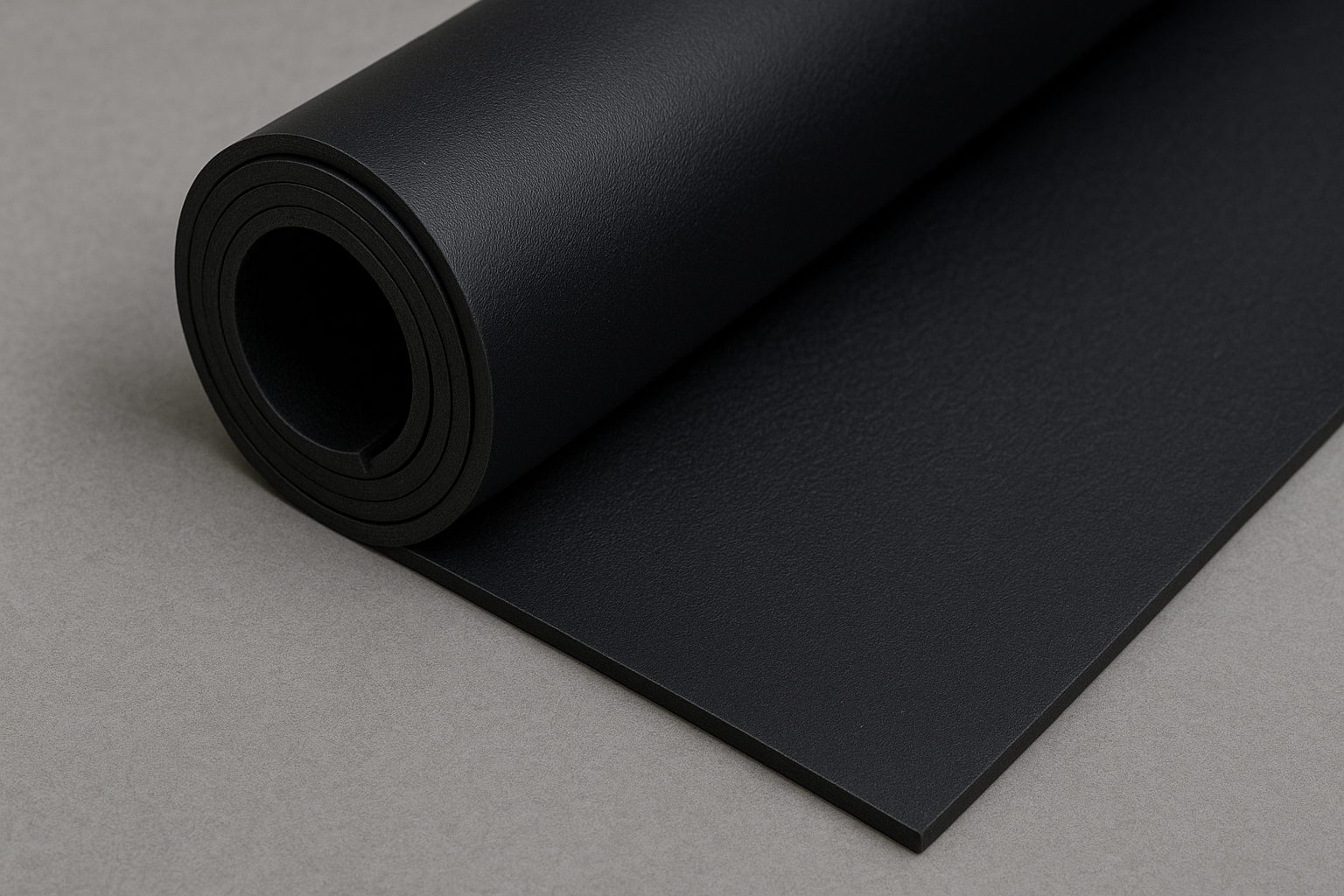

Nitrile Properties: Key Features and Benefits

Nitrile rubber, or Nitrile Butadiene Rubber (NBR), is a synthetic elastomer made from acrylonitrile and butadiene. Known for its nitrile properties, it offers excellent resistance to oils, fuels, and chemicals, making it ideal for automotive, aerospace, and industrial applications. The acrylonitrile content, which ranges from 14% to 50%, directly affects its resistance to oils.

This material performs well across a wide temperature range (-40°F to +250°F / -40°C to +120°C) and is valued for its durability, including high tensile strength and low compression set. However, nitrile rubber can degrade when exposed to ozone and UV light, limiting its use in outdoor environments.

Is Nitrile Biodegradable?

Nitrile rubber is not biodegradable in the traditional sense. As a synthetic polymer, it does not break down naturally like organic materials and can persist in landfills for extended periods.

However, nitrile excels in durability, chemical resistance, and performance in demanding applications. It is a trusted choice for fuel hoses, oil seals, and gaskets where long-lasting, reliable sealing is essential.

For applications requiring greater weather or ozone resistance, EPDM rubber is an excellent alternative that we also offer.

Does Nitrile Conduct Electricity?

Nitrile rubber is non-conductive, which means it provides excellent electrical insulation. This property makes nitrile a reliable material for seals, gaskets, and protective covers where electrical isolation is important.

Its balance of oil resistance and insulating capability makes nitrile ideal for automotive, aerospace, and industrial applications. If your project requires additional resistance to weathering or UV exposure, EPDM rubber may be a better fit.

Nitrile Rubber Density

Nitrile rubber typically has a density ranging from 1.23 to 1.30 g/cm³, depending on the specific formulation and the presence of any fillers or additives. This density range means nitrile rubber is relatively dense compared to other elastomers, contributing to its durability and resistance to wear and tear.

The density of nitrile rubber plays a crucial role in its performance in different applications. For example, in seals and gaskets, the material’s density ensures a tight fit and effective sealing capability. In other uses, such as hoses or cushions, the density helps provide the necessary strength and stability while maintaining flexibility.

Nitrile Rubber Manufacturers

At Enterprise Rubber, we specialize in providing high-quality nitrile rubber solutions tailored to meet the unique needs of various industries. Our nitrile rubber products are recognized for their exceptional chemical resistance, durability, and versatility, making them ideal for demanding applications in automotive, manufacturing, and industrial sectors.

We offer a wide range of nitrile rubber components, including vibration isolators, mounts, and custom molded parts, all manufactured in the USA at our Ohio facility. Our nitrile rubber products are designed to perform reliably even in challenging environments, ensuring long-lasting performance and value for our clients.

With over 50 years of experience, Enterprise Rubber is committed to delivering nitrile rubber solutions that uphold the highest quality standards, supporting industries that rely on durable and versatile materials for their critical applications.

Need Custom Nitrile (NBR) Parts?

Get U.S.-made, production-ready components engineered for oil, fuel, and chemical exposure. We mold seals, gaskets, hoses, mounts, and vibration isolators to your spec.

Contact Us