Description

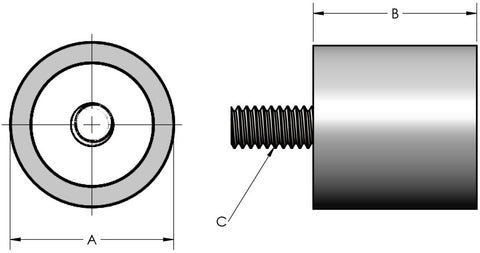

Round Rubber Mounts with Male End Only are often used as feet and bumpers, typically screwed into applications at intervals to protect from striking or bumping as well as to support static load.

Round Rubber Mounts with Thread to Screw-In

- Typically used as anti-vibration isolation pads that require the properties of rubber

- Applications by industry for one end only anti-vibration round rubber mounts; furniture, rubber door stops, rubber window stops, industrial, aerospace, automotive, OEM, transportation, construction, healthcare, research, oil, and gas

- Sample product applications for vibration isolator mount industrial rubber mounts, machine vibration isolation, HVAC, vacuum, engine, aerospace, motors, fans, medical equipment, and electronics

- Often referred to as anti-vibration isolation pads, round rubber mounts, anti-vibration rubber mounts, vibration isolation mounts, rubber isolation mounts, rubber vibration isolator, rubber engine mounts, spring vibration isolators, rubber motor mounts

What Rubber Is Used For Motor Mounts?

Neoprene rubber is chosen for its excellent resistance to oil, heat, and environmental factors, making it well-suited for the demanding conditions in an engine compartment. Neoprene motor mounts provide the necessary flexibility and damping properties to absorb engine vibrations and isolate them from the vehicle's chassis, ultimately enhancing the comfort and stability of the vehicle.

What Is The Difference Between Solid and Rubber Motor Mounts?

The primary difference between solid motor mounts and rubber motor mounts lies in their construction and how they handle vibrations:

Solid Motor Mounts:

- Solid motor mounts are made from rigid materials, such as metal or hard plastic, without any elastomeric (rubber-like) components.

- They provide a firm, direct connection between the engine and the vehicle's chassis, which limits the engine's movement.

- While solid motor mounts offer greater stability and support, they do not effectively absorb or dampen engine vibrations and may transmit more noise and harshness into the vehicle's cabin.

- Rubber motor mounts, as the name suggests, contain elastomeric rubber or similar materials.

- They provide a flexible connection between the engine and the chassis, allowing for some degree of movement.

- Rubber motor mounts effectively absorb and dampen engine vibrations, reducing noise and providing a smoother and more comfortable ride.