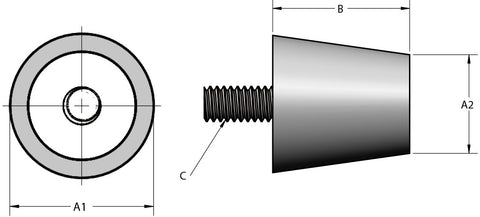

Description

The tapered style rubber bumper is often used as feet and bumpers, typically screwed into applications at intervals to protect from striking or bumping. This style of tapered rubber bumper can also support the static load. Tapered styles are sometimes preferred for stability and precision.

Tapered Vibration Isolator Rubber Bumper

- Tapered rubber bumpers one male, threaded insert end on the large end

- Typically used as anti-vibration isolation pads that require the properties of rubber absorption

- Applications by industry for male large end only anti-vibration rubber bumper include industrial, aerospace, automotive, OEM, transportation, construction, healthcare, research, oil, and gas

- Sample product applications for a rubber bumper include machine vibration isolation, HVAC, vacuum, engine, aerospace, motors, fans, medical equipment, and electronics

- Often referred to as rubber bumpers, anti-vibration isolation pads, rubber mounts, vibration isolation pads, anti-vibration rubber mounts, vibration isolation mounts, rubber isolation mounts, rubber vibration isolator, rubber engine mounts, spring vibration isolators, rubber motor mounts

What Is a Rubber Bumper?

A rubber bumper is a small, resilient component made of rubber. It is typically attached to the surface of an object to provide protection and dampening. Rubber bumpers are used to absorb and dissipate impacts, preventing damage, noise, and wear. They can be found on various items, such as furniture legs, doors, automotive components, and machinery, serving to cushion impacts, reduce vibrations, and provide a soft barrier to protect surfaces and objects from contact-related damage.

Why Are Bumpers Made of Rubber Instead of Metal?

Bumpers are often made of rubber instead of metal for several reasons:

- Impact Absorption: Rubber is a resilient and flexible material that can effectively absorb and dissipate the energy from impacts, reducing the force transferred to the objects or surfaces they protect. Metal, on the other hand, is rigid and does not absorb energy as effectively.

- Vibration Damping: Rubber bumpers can also dampen vibrations, which is essential in applications where the transmission of vibrations needs to be minimized, such as in machinery and vehicles.

- Noise Reduction: Rubber bumpers significantly reduce noise when objects come into contact with them, providing a quieter and more comfortable environment.

- Surface Protection: Rubber bumpers are gentle on surfaces and objects, preventing scratches, dents, and damage that can occur when metal bumpers are used.

- Corrosion Resistance: Rubber is not prone to rust or corrosion, making it a durable choice, especially in outdoor or humid environments.

- Cost-Efficiency: Rubber bumpers are often more cost-effective to manufacture and replace than metal alternatives.