Description

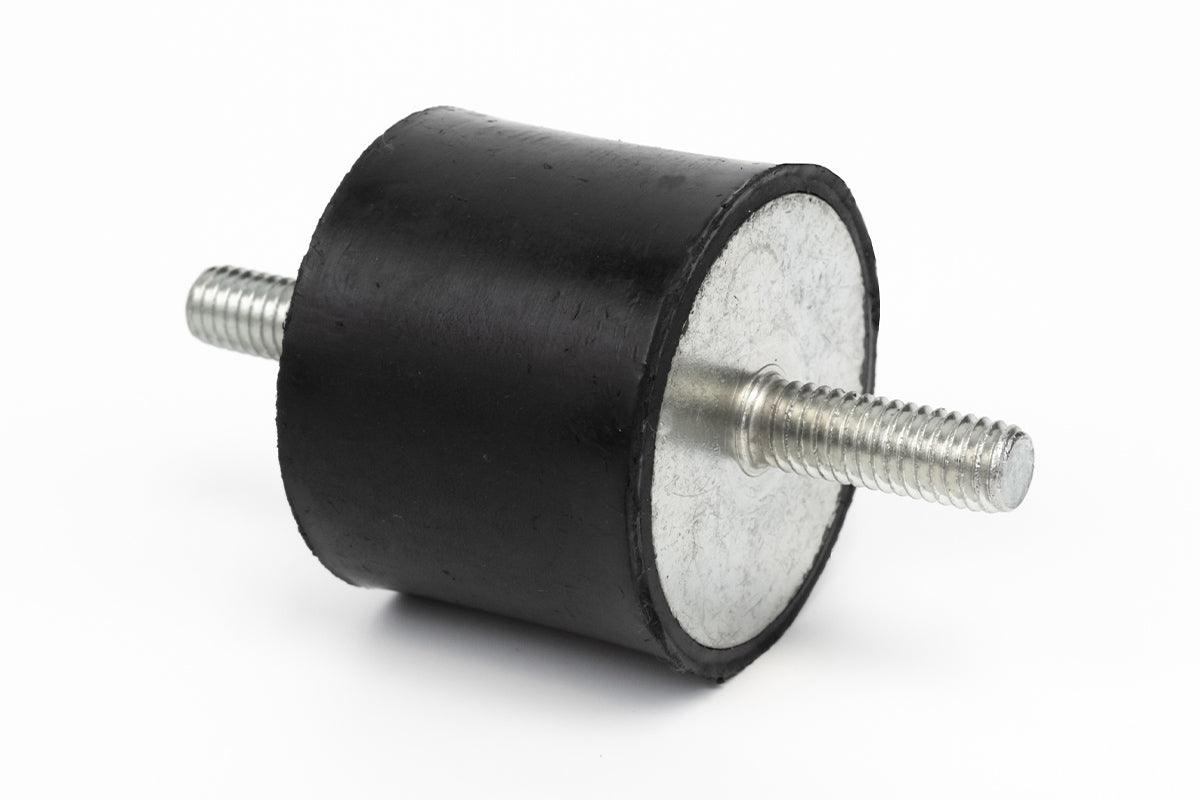

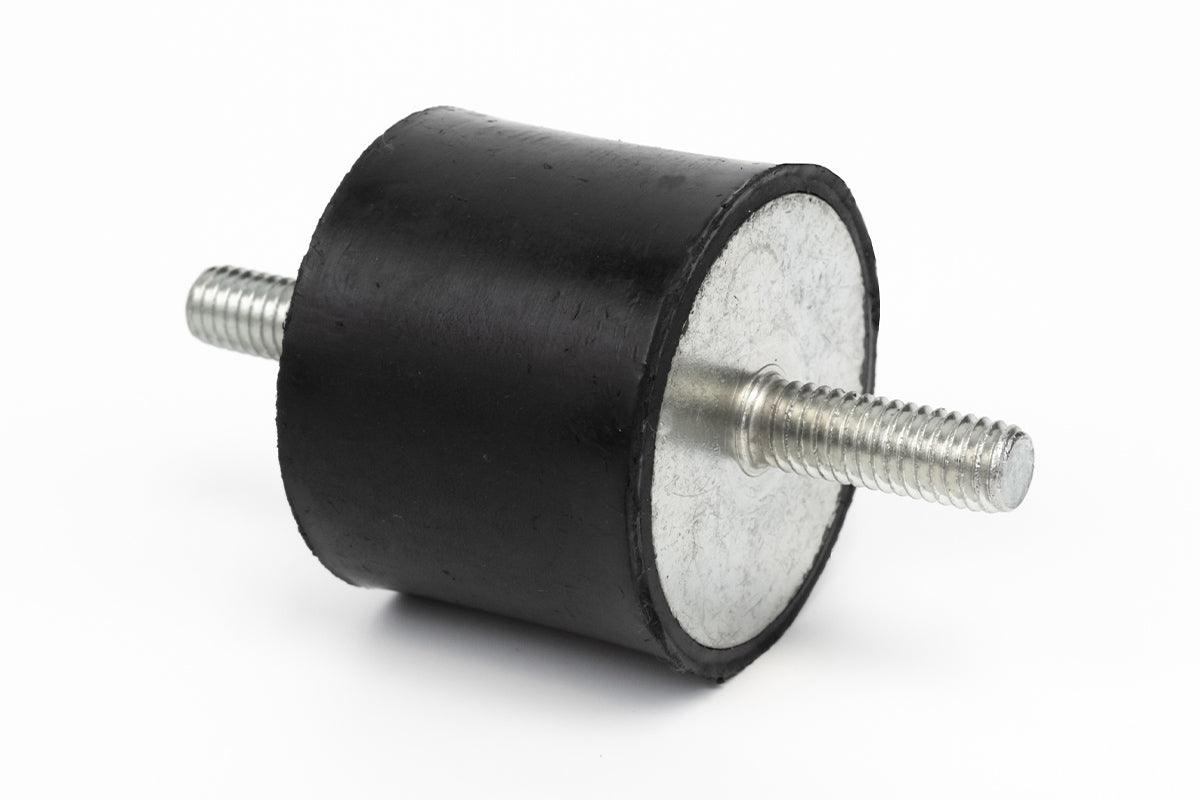

Rubber isolators are a common mount typically used as a double studed, sandwich-style mount between two areas of vibration in mechanical and electrical applications.

Rubber Isolators with Male/Male Both Ends

- Typically used as anti-vibration isolation pads that require the properties of rubber or elastomers

- Applications by industry for rubber isolators with male/male both ends anti-vibration rubber mounts; industrial, aerospace, automotive, OEM, transportation, construction, healthcare, research, oil, and gas

- Sample product applications for rubber vibration isolator male/male both ends, mount industrial vibration isolators, machine vibration isolation, HVAC, vacuum, engine, aerospace, motors, fans, medical equipment, and electronics

- Often referred to as anti-vibration isolation pads, rubber mounts, vibration isolation pads, anti-vibration rubber mounts, vibration isolation mounts, rubber isolation mounts, rubber vibration isolator, rubber engine mounts, spring vibration isolators, rubber motor mounts

What Is The Difference Between a Vibration Absorber and a Vibration Isolator?

The primary difference between a vibration absorber and a vibration isolator lies in their function and how they address vibrations:

Vibration Absorber:- A vibration absorber is a device or component designed to reduce the amplitude of vibrations by absorbing their energy.

- Vibration absorbers are often used to minimize resonant vibrations in systems or structures by altering their natural frequency.

- A vibration isolator, also known as a shock mount or anti-vibration mount, is a device designed to prevent vibrations from transmitting from one component or structure to another.

- Isolators use materials like rubber or elastomers to provide a flexible connection between the vibrating source and the structure or equipment it's mounted on.

- The primary function of a vibration isolator is to isolate and dampen vibrations, protecting sensitive equipment and reducing noise.

How Do You Size a Vibration Isolator?

To size a vibration isolator, first identify the vibration source and its characteristics, calculate the equipment's weight and load distribution, consider environmental factors, select the appropriate isolator type, determine the required isolation level, consult manufacturer data for matching specifications, and take into account installation and maintenance requirements. Consulting with experts or the isolator manufacturer can ensure the correct selection and sizing for your specific application, enhancing vibration reduction and equipment protection.

What Are The Different Types of Vibration Isolators?

Vibration isolators can be made from a variety of rubber materials with varying durometer (hardness) ratings. Knowing the application and the desired hardness of the vibration isolator will help you select the right vibration isolator for your application.